Vodacom Battery Solutions

We are delighted to collaborate with Vodacom South Africa to drive innovation and security excellence in the telecommunications industry, which…

Plug and play to change over from lead acid batteries for unrivalled lifetime cost and carbon emission savings.

Drastically reduce your cost of ownership and carbon emissions.

Fridge.li is designed electric for a better future, with safety and telematics at its core.

Zero carbon. Low cost. High power. Long lasting. Electrifying the reefer industry with innovative and scalable solutions for semitrailers.

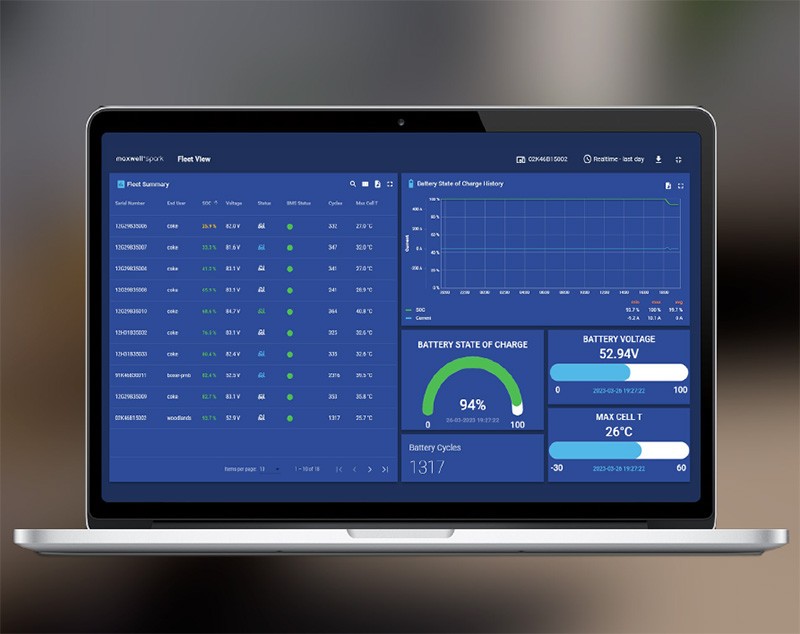

TELEMETRY

Rely on our customisable, intelligent fleet reporting with over-the-air updates. Collect and visualise essential data to allow you to process and react – reduce breakdowns, improve safety and identify growth opportunities.

Built inhouse on AWS AI to give you peace of mind and give you a complete solution for fleet monitoring and reporting.

Latest updates

We are delighted to collaborate with Vodacom South Africa to drive innovation and security excellence in the telecommunications industry, which…

7 Reason why lithium-ion phosphate batteries are better than other lithium-ion batteries At maxwell+spark we understand that not all lithium-ion…

Maxwell+Spark at MODEX 2024! What an electrifying experience at MODEX 2024 (11-14 March Atlanta,USA)! As the curtains close on this…

Lithium-ion technology stands at the intersection of progress and pollution. This is a tricky line to navigate, and at maxwell+spark…

Innovation, quality and safety have always been foundational factors in the design and manufacture of maxwell+spark’s LiFePo4 batteries. With the…

While we might be growing all over the globe, our roots are firmly planted in South Africa. As a result,…

Our first Vodacom HSBC was installed on 29 September, just South of Durban, and marks another successful maxwell+spark solution to…

We are proud to announce a co-funded project of € 2,5 million between maxwell+spark and the Just Transition Fund (JTF)…

In today’s world, the demand for cleaner and more efficient energy solutions is growing at an unprecedented rate. Industries are…

There is a difficult question that needs to be asked when talking about sustainability and cutting carbon emissions, especially in…

Problems such as how to secure batteries at Vodacom cell phone tower sites across South Africa. Last week we welcomed…

Amidst summer’s distraction of ice-cream, cooling off in whatever expanse of water is available and the busy whir of fans,…

As the demand for clean energy solutions continues to grow, innovations and advancements in battery technology become central to how…

Contributing actively to the green energy transition in the refrigerated food and logistics industry is a goal shared by maxwell+spark…

From frozen peas to ice-cream, to dairy and fresh vegetables, the cold chain ensures that products reach their destination in…